Description

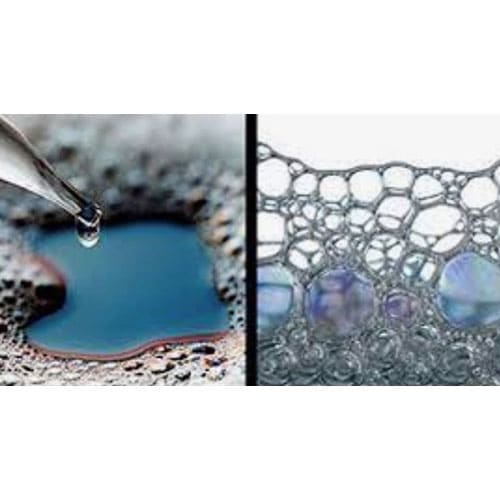

Anti-foaming agents, also known as defoamers or foam control agents, are additives used in paint formulations to prevent or reduce foam formation during manufacturing, mixing, application, and storage. Foam can negatively impact the performance and appearance of the paint, and anti-foaming agents work by destabilizing and breaking down the foam bubbles. Here are common types of anti-foaming agents used in paints:

1. Silicone-Based Defoamers:

- Examples:

- Polydimethylsiloxane (PDMS)

- Silica-based silicone defoamers

- Functions:

- Highly effective in controlling foam.

- Compatible with a wide range of paint formulations.

- Provide long-lasting foam control.

2. Non-Silicone Defoamers:

- Examples:

- Mineral oil-based defoamers

- Vegetable oil-based defoamers

- Functions:

- Offer alternatives to silicone-based defoamers.

- Can be used in formulations where silicone is not desired.

3. Water-Based Defoamers:

- Examples:

- Emulsion defoamers

- Polymer-based defoamers

- Functions:

- Specifically designed for water-based paint formulations.

- Provide effective foam control in aqueous systems.

4. Powder Defoamers:

- Examples:

- Powdered silica defoamers

- Functions:

- Offer convenience in handling and storage.

- Can be easily dispersed in paint formulations.

5. Oil-Based Defoamers:

- Examples:

- Hydrophobic compounds, such as fatty acid esters

- Functions:

- Effective in oil-based paint formulations.

- Provide excellent foam control in solvent-based systems.

6. Polymer-Based Defoamers:

- Examples:

- Polyethylene glycol (PEG)-based defoamers

- Polyacrylate-based defoamers

- Functions:

- Act by disrupting the foam structure.

- Compatible with various types of paints.

Considerations for Anti-Foaming Agent Selection:

- Compatibility: Ensure compatibility with other components in the paint formulation.

- Effect on Coating Performance: Evaluate the impact of the anti-foaming agent on the properties of the final paint coating.

- Application Method: Consider the intended application method (brushing, rolling, spraying) and adjust the anti-foaming agent accordingly.

- Regulatory Compliance: Choose anti-foaming agents that meet regulatory standards, especially in terms of VOC content.

It’s important to note that while anti-foaming agents effectively control foam, excessive use may lead to surface defects or other issues. Therefore, the dosage of anti-foaming agents should be carefully optimized based on the specific paint formulation and application requirements. Additionally, manufacturers may need to test and adjust formulations to find the most effective anti-foaming agent for their particular paint system.

Reviews

There are no reviews yet.