Description

The supply of hardwood involves various processes and stakeholders, from the harvesting of hardwood timber to the distribution and sale of hardwood products. Hardwood is derived from deciduous trees with broad leaves, and it is valued for its durability, strength, and aesthetic qualities. Here are key aspects of the hardwood supply chain:

- Harvesting:

- Forestry Practices: Hardwood is often harvested from sustainably managed forests, where selective logging methods are employed to ensure the long-term health and productivity of the forest.

- Logging Operations: Professional loggers or forestry companies carry out the harvesting process, carefully selecting mature trees for extraction.

- Processing:

- Sawmills and Processing Facilities: Harvested logs are transported to sawmills or processing facilities, where they undergo cutting, milling, and drying processes.

- Lumber Grading: Hardwood lumber is graded based on quality, with different grades suitable for various applications, such as furniture, flooring, and construction.

- Distribution and Wholesale:

- Wholesalers and Distributors: Processed hardwood products, including lumber, veneers, and engineered wood, are distributed to wholesalers and distributors.

- Global Trade: Hardwood is often traded globally, with international markets playing a significant role in the supply chain.

- Manufacturing:

- Woodworking Industries: Manufacturers in various industries, such as furniture, flooring, cabinetry, and construction, use hardwood to create a wide range of products.

- Value-Added Processing: Some hardwood is processed further to create value-added products like furniture components, moldings, and specialty items.

- Retail and Consumer Markets:

- Retailers: Finished hardwood products reach retail outlets, including home improvement stores, specialty lumberyards, and furniture retailers.

- Consumer Market: Consumers purchase hardwood products for use in homes, construction projects, and various applications.

- Sustainability and Certification:

- Sustainable Practices: Increasingly, there is a focus on sustainable forestry practices to ensure the responsible management of hardwood resources.

- Certification Programs: Certification bodies, such as the Forest Stewardship Council (FSC), provide certification to wood products sourced from sustainably managed forests.

- Challenges and Opportunities:

- Illegal Logging: Addressing issues related to illegal logging and promoting legality in the hardwood supply chain.

- Global Demand: Meeting the growing global demand for hardwood products while balancing environmental concerns.

- Regulatory Compliance:

- Government Regulations: Compliance with local and international regulations related to forestry practices, logging permits, and trade agreements.

- Innovation:

- Engineered Wood Products: Advances in technology have led to the development of engineered wood products, providing alternative solutions to traditional hardwood.

- Recycling and Reuse:

- Wood Recycling: Some hardwood products can be recycled or repurposed, contributing to sustainability efforts.

Considerations for Hardwood Buyers:

- Species Selection: Different hardwood species have unique characteristics, and buyers should consider the specific qualities required for their intended use.

- Certification: Choose hardwood products with certification from recognized sustainability programs, such as FSC, to support responsible forestry practices.

- Quality and Grade: Assess the quality and grade of hardwood products based on intended applications and aesthetic preferences.

- Supplier Relationships: Establish relationships with reputable suppliers and distributors to ensure a reliable and consistent supply of hardwood.

Hardwood supply chains can vary based on geography, industry practices, and market dynamics. Sustainable and responsible sourcing practices are increasingly important considerations in the hardwood industry to ensure the long-term viability of hardwood resources.

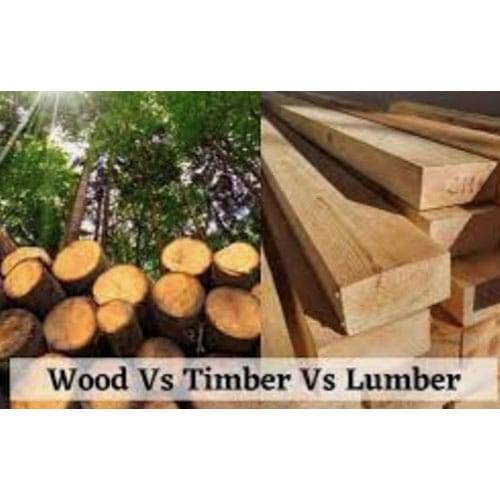

The terms « hardwood, » « timber, » and « lumber » are often used in the context of the wood industry, but they refer to different aspects of wood and wood products. Here’s a breakdown of the distinctions:

- Hardwood:

- Definition: « Hardwood » is a term used to classify wood from deciduous trees, which are characterized by broad leaves and generally slower growth compared to softwood (coniferous) trees.

- Examples: Oak, maple, mahogany, teak, and cherry are examples of hardwood species.

- Characteristics: Hardwoods are known for their density, durability, and a variety of applications, including furniture, flooring, cabinetry, and decorative items.

- Usage: Hardwoods are often favored for high-quality furniture and interior finishes due to their aesthetic appeal and strength.

- Timber:

- Definition: « Timber » is a term that can have different meanings depending on the context. In a general sense, it refers to wood that has been prepared for use in construction or other applications.

- Examples: Timber can refer to wood in various forms, including logs, beams, planks, and boards.

- Usage: « Timber » is commonly used when referring to wood in the context of construction, structural components, or building materials. For example, « structural timber » refers to wood used for framing in buildings.

- Lumber:

- Definition: « Lumber » is wood that has been processed into standardized forms, such as boards, planks, or beams, typically for use in construction or other applications.

- Examples: Lumber includes various wood products, such as dimensional lumber, boards, and planks.

- Characteristics: Lumber is often categorized by size, grade, and species. It can be further processed for specific uses, such as framing lumber, sheathing, or finishing materials.

- Usage: Lumber is a versatile term encompassing wood products used in various construction and woodworking applications.

Summary:

- Hardwood refers to wood from deciduous trees, known for its density, strength, and diverse applications in furniture and interior finishes.

- Timber is a broader term that generally refers to wood prepared for construction, including logs, beams, or processed wood used in building structures.

- Lumber specifically refers to processed wood products, such as boards and planks, that have been cut and shaped for use in construction or other applications.

It’s important to note that the use of these terms can vary regionally and contextually. In some regions, the term « timber » is used more broadly, while in others, « lumber » may be the preferred term for processed wood products. Understanding the specific context and industry practices is crucial for accurate communication in the field of wood and construction.

Reviews

There are no reviews yet.