Description

Vietnam is a growing producer and exporter of wood pellets, which are a type of biomass fuel made from compressed sawdust and wood shavings. Wood pellets are used for heating, as a renewable energy source, and in industrial applications. Here’s an overview of wood pellet production in Vietnam:

Production Process:

- Raw Materials: Wood pellets in Vietnam are typically produced from a variety of raw materials, including sawdust, wood shavings, wood chips, and wood residues from the forestry and wood processing industries.

- Drying: The raw materials are dried to reduce their moisture content, typically to around 10% or less. Low moisture content is crucial for efficient pellet production and combustion.

- Size Reduction: The dried wood material is then processed to reduce its size into small particles, which are then used to make pellets.

- Pelletization: The reduced wood material is compressed into small cylindrical pellets using a pellet mill. During this process, heat and pressure are applied to bind the wood particles together without the need for additives or binders.

- Cooling: The newly formed wood pellets are cooled to room temperature to ensure they are solid and durable.

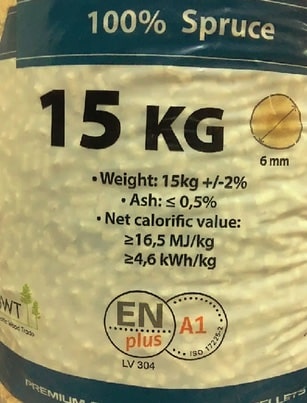

- Screening and Quality Control: The pellets are screened to remove any fines or irregular pellets. Quality control measures are taken to ensure the pellets meet the required standards for size, density, and moisture content.

Characteristics of Vietnamese Wood Pellets:

- Quality: Vietnamese wood pellets are known for their quality and consistency. They typically meet international standards for wood pellet production.

- Sustainability: Many Vietnamese wood pellet producers source their raw materials from sustainably managed forests, contributing to environmentally friendly production.

- Export: Vietnam exports wood pellets to various international markets, including Europe, where they are used for residential and industrial heating.

- Energy Efficiency: Wood pellets are considered an environmentally friendly and efficient source of renewable energy. They have low moisture content, which results in a high energy content per unit of volume.

- Industrial Use: In addition to residential heating, Vietnamese wood pellets are also used in industrial applications, including co-firing in power plants and as a source of heat in industrial processes.

Vietnamese wood pellets have gained recognition for their quality and sustainability, making them a competitive choice in the global wood pellet market. They are considered a renewable energy source and are used for various heating and industrial purposes, contributing to both domestic and international energy needs.

Malaysia is also a producer and exporter of wood pellets, which are commonly used as a renewable source of energy for heating and industrial applications. Malaysian wood pellets share similarities with those from other countries, including Vietnam, and they have specific characteristics that make them suitable for various uses. Here’s an overview of wood pellet production in Malaysia:

Production Process:

- Raw Materials: Malaysian wood pellets are typically made from sawdust, wood shavings, wood chips, and other wood residues, including those from the timber and wood processing industries.

- Drying: The raw materials are dried to reduce their moisture content, usually to around 10% or less, to ensure optimal pellet production and combustion efficiency.

- Size Reduction: The dried wood material is processed to reduce its size into small particles, which are then used to create pellets.

- Pelletization: The reduced wood material is compressed into small cylindrical pellets using a pellet mill. Heat and pressure are applied to bind the wood particles together without the need for additives or binders.

- Cooling: The newly formed wood pellets are cooled to room temperature to ensure they are solid and durable.

- Screening and Quality Control: The pellets are screened to remove any fines or irregular pellets. Quality control measures are taken to ensure the pellets meet the required standards for size, density, and moisture content.

Characteristics of Malaysian Wood Pellets:

- Quality: Malaysian wood pellets are known for their quality and consistency. They typically meet international standards for wood pellet production, including specifications for size, density, and moisture content.

- Sustainability: Many Malaysian wood pellet producers source their raw materials from sustainably managed forests, contributing to environmentally friendly production.

- Export: Malaysia exports wood pellets to various international markets, where they are used for residential heating, industrial applications, and as a renewable energy source.

- Energy Efficiency: Wood pellets have low moisture content, which results in a high energy content per unit of volume, making them an efficient source of renewable energy.

- Industrial Use: Malaysian wood pellets are used in both residential heating and industrial applications, including co-firing in power plants and as a source of heat in industrial processes.

Malaysian wood pellets have gained recognition for their quality and sustainability, making them a competitive choice in the global wood pellet market. They are considered a renewable energy source and are used for various heating and industrial purposes, contributing to both domestic and international energy needs. Importers and buyers often consider the specific requirements and certifications, such as those related to sustainability and environmental standards, when making their purchasing decisions

Reviews

There are no reviews yet.